There are some simple tests that you can do at this stage to find out whether the soil has clay in it, and

whether it can be used for pottery. Remove any twigs and stones, then knead a handful of the soil (add

some water if it is too dry). Try to roll it into a long thin snake shape and coil this into a circle. If you can

do this without the soil cracking then the soil has quite a lot of clay in it and may be suitable for pottery.

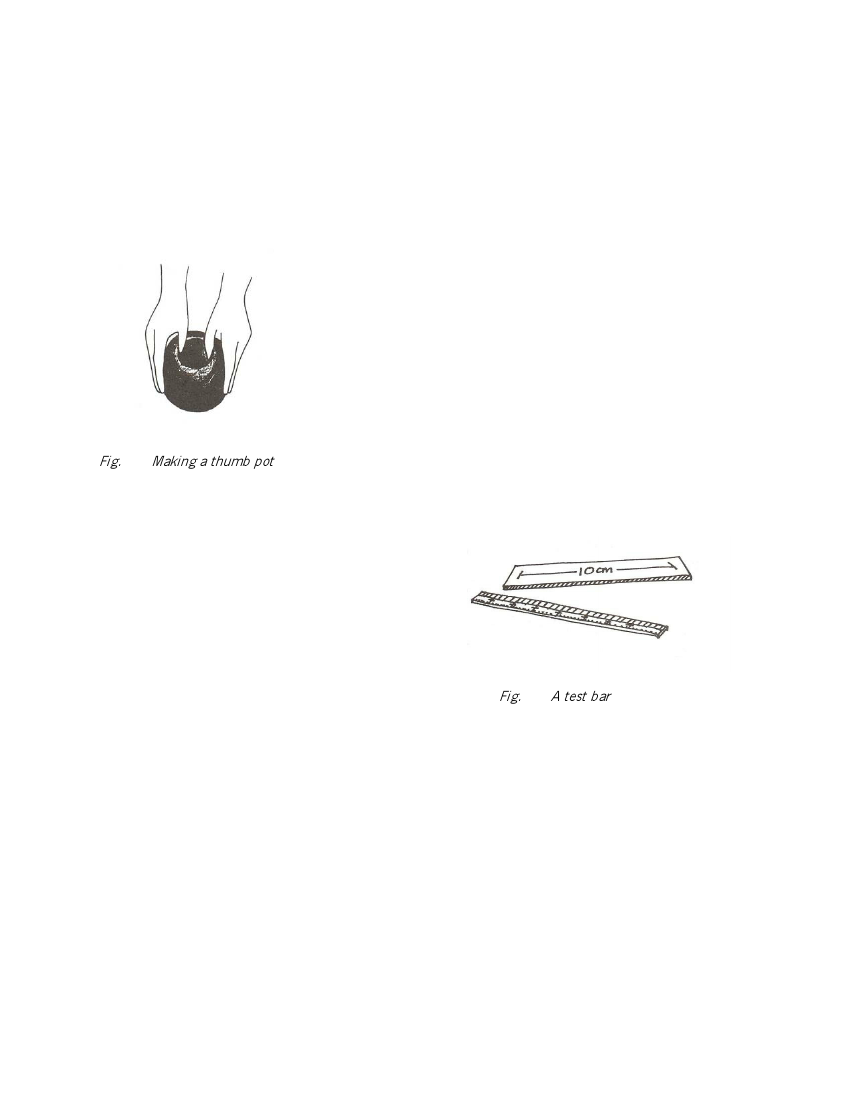

You can also try to make a small thumb pot from the clay. Take a small handful of the soil and roll it into a

ball (about 2-3 cm diameter), then push your thumb into the ball and squeeze the clay between your

thumb and finger, gradually forming a small pot. If you are able to make a pot, you have found a pottery

clay that may be suitable for producing stove liners.

Fig. 2.3 Making a thumb pot

These tests will give you an indication of whether you have found usable

clay. It is important to remember that not all pottery clays are good for

making stoves. Therefore, you will need to test the clay further before you

are sure it is suitable. A simple test to find out if your clay is suitable for

stove liner production is to measure the shrinkage of the clay. Make several

test bars which are 15 x 5 x 1 cm. Mark a length of exactly 10 cm on each

bar, dry them for at least a week, and fire them. Measure between the

original 10cm marks. If the original 10 cm marks are still more than 9 cm

apart, you may have a suitable clay. If the 10 cm has shrunk to less than 9

cm (i.e. the shrinkage is more than 10%) the clay is not likely to be suitable

for making stoves. Nevertheless, you can try adding more sand to the clay

and repeating the test.

The only sure test to find out if the clay is suitable for stoves is to take it through the whole process of

moulding, drying and firing. Then try building and using some stoves for cooking to see if they are strong

and will last.

Ideally, you need to find a source of clay that is large

enough to last for at least a few years. Otherwise you will

need to keep testing new sources. You should also

consider whose land the clay is on, whether you will be

allowed to collect clay there and if you have to pay for it.

If the clay is a long way from your workshop, you should

also calculate the cost of transporting it.

Fig. 2.4 A test bar

Do you have all the materials you need?

You will need a source of water, an adequate supply of fuel for firing and a source of fine sand to mix with

the clay. Some clays contain sand when they are dug from the ground. Others are mostly pure clay. As

clays with high sand content are best for making liners, even if local potters do not mix sand into their clay

for making pots, you will probably need additional sand in the clay for making stove liners. If sand is not

available, you can use grog. These are broken pieces of pottery ground to a coarse powder.

Equipment and work space

Stove liner production requires investment of time, money and other resources such as working space. The

mould equipment will cost at least £ 100. In addition, you will need a place to work and a place to store

liners while they are drying. Although you can start production on a small scale by working under a tree and

storing liners in your house, if it is to become a viable business, in the longer term you will need to invest

in a workshop and a kiln. Production economics in Kenya indicate that making fewer than 100 stoves a

month is not viable.